Materials:Q355B

Main Parameters

Item No :

SY650HDPayment :

TTProduct Origin :

China FujianShipping Port :

XIAMENLead Time :

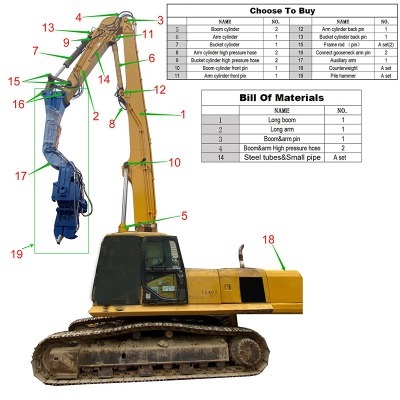

30daysEXCAVATOR PILE DRIVING ARM & BOOM

The SY650HD Piling Boom is a heavy-duty, reinforced excavator arm specially designed for foundation construction, bridge piling, cofferdam projects, and high-impact pile driving environments.

Manufactured by Heng Wei Machine (Zhangzhou) Co., Ltd., this boom is engineered to perfectly fit the SANY SY650HD (65 tons) excavator model.

Constructed with Q355/Q690 high-strength steel and processed using robotic welding, CNC cutting, and full ultrasonic inspection, the SY650HD piling boom offers exceptional durability, stability, and vibration resistance required for pile hammer operations.

We provide fully customizable designs according to pile hammer brand, excavator requirements, working conditions, and hydraulic system configurations.

▎KEY FEATURES

Designed with reinforced boom plates, thickened structures, and extra ribs to handle strong vibration from hydraulic pile drivers.

Bracket, pin sizes, hydraulic pipe routing, and mounting points are customized for SANY SY650HD excavators.

Low-flex design improves accuracy and reduces energy loss during hammer impact.

Anti-corrosion coating ensures long-term durability in construction, offshore, and foundation projects.

Boom length

Hammer interface

Extra hydraulic lines

High-strength steel options

Reinforced bottom structure

▎CONFIGURATION SITUATION

▎STEEL CUTTING

The incision is flat to ensure the accuracy of cutting steel plates

▎GROOVE WELDING

Before welding, we have use big edge milling machine mill(taper process) the edge of the sheet. So the welding can go to the internal of the steel-sheet and make the structure have higher performance.

Orbital welding machines are used for welding, and manual strengthening and welding are performed at corners and reinforcements.

Our boom and arm are large-welded box structure and thick or multi-plates for high-stress areas.

Also the inside have strength plate make it more stronger.

▎LARGE BORING MACHINE -- BUTT BORING

The processing efficiency is higher, the precision is better, and the product quality and labor efficiency are greatly improved.

▎SURFACE TREATMENT OF WORKPIECE--SHOT BLAST

The small steel balls of the large shot blasting machine are used to hit the surface of the workpiece to remove the rust and small impurities on the surface of the steel plate, so that the surface of the workpiece presents the original metallic luster and increases the adhesion of the primer.

▎PRIMER AND PAINT TREATMENTS

Spray with the same paint as the brand excavator factory to ensure consistent color.

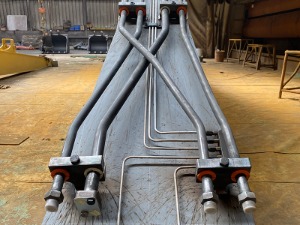

▎HIGH PRESSURE HARD PIPE & PIPELINE BENDING TREATMENT

1. Friction welded flange and oil cylinder - use machine high-speed friction welding, which has higher efficiency and avoids artificial false welding and air bubbles.

2. Automatic pipe bending machine - use numerical control to control the degree of bending of the pipeline, and automatically bend the seamless steel pipe, with higher precision.

▎PAINT / PACKAGING / TRANSPORTATION SERVICES

1.The color paint is consistent with the brand excavator factory (customizable color), using high-quality paint to make the product more delicate and beautiful.

2. We use stretch film to package the product. (Three-plywood wooden frame needs to be noted)

3. We have cooperated with many shipping companies in China for many years,and the transportation service and efficiency are very good. (Recommend FOB/CIF/CNF)

▎CERTIFICATTES & FACTORY HISTORY

We were originally affiliated to a Singaporean private factory in China. We have always only served the excavator industry and have a lot of data and manufacturing experience. Provide professional excavator accessories for dealers in many countries around the world.We insist on quality first, and deal with details so that brand dealers appoint us as partners.

(Information and photos are not displayed to protect the privacy of customers)